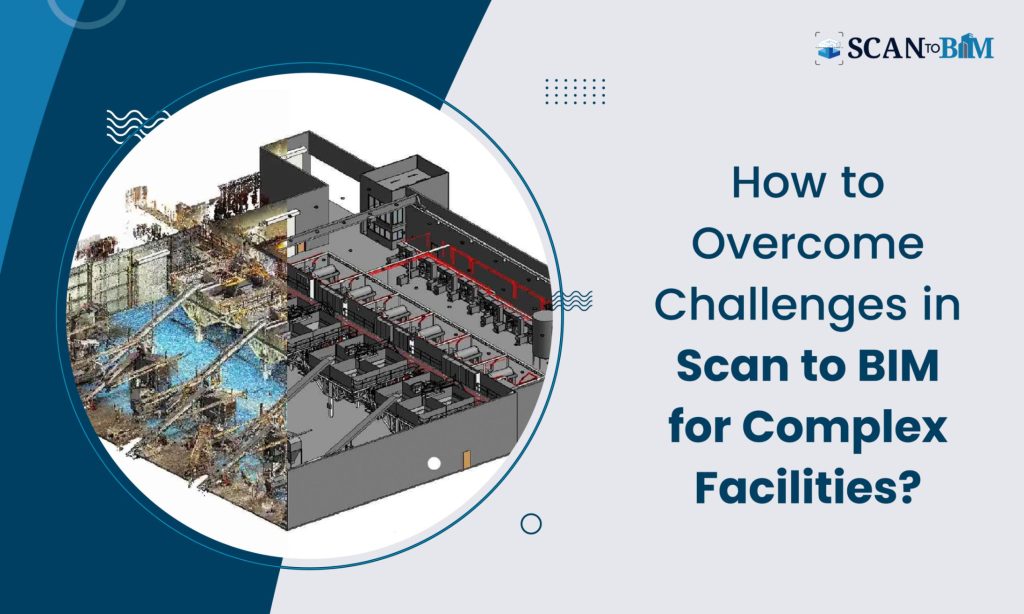

The AEC industry has been steadily embracing the Scan to BIM technology to bridge the gap between the as-built environments and the digital models. By converting the point cloud data obtained from the 3D laser scanning into the intelligent BIM models, stakeholders can gain a precise and comprehensive representation of any of the existing structures. This process is particularly valuable in renovation, retrofit, facility management and heritage conservation projects where accuracy is paramount.

However, the path from the point clouds to functional BIM is not always smooth—especially when dealing with the complex building structures such as historical monuments, hospitals, airports, stadiums or industrial facilities. These projects introduce unique challenges that goes far beyond the standard scanning and modeling. Overcoming these challenges demands a combination of advanced technology, strategic foresight and also the industry expertise.

In this blog, we will go through the key challenges of Scan to BIM in the complex building structures and the strategies to overcome them.

The Challenges in Scan to BIM for Complex Structures

1) Sheer Scale and Intricacy of Structures

Complex buildings—such as airports, industrial plants or multi-block campuses often extend across vast areas with highly detailed elements. Capturing such detail through the laser scans generates the massive datasets that are difficult to process, manage and convert into usable BIM models.

Why it’s a challenge:

- Large file sizes slows down the processing and strains the system capabilities.

- Intricate geometries (e.g., curved façades, ornate details, or mechanical systems) requires intensive modeling efforts.

2) Data Quality and Accuracy of Point Clouds

Even the best scanning equipment can encounter obstacles like occlusions, reflective surfaces or inaccessible areas. These leads to gaps, noises or distortions in the point cloud data. For the complex structures with hidden or overlapping elements, missing data can compromise the model accuracy.

Why it’s a challenge:

- Inaccurate data causes errors in the BIM model.

- Multiple scans from the different angles requires precise registration.

- Safety and accessibility concerns sometimes limits the scanning options.

3) Irregular and Non-standard Geometry

Heritage sites, old buildings or unique architectural designs often have non-standard geometries that deviate from the modern construction norms. Modeling these irregularities in BIM—which is often built on the standardized components—can be extremely time-consuming.

Why it’s a challenge:

- Standard BIM libraries may not support the irregular forms.

- Custom families needs to be created, increasing cost and time.

- Striking a balance between the model accuracy and usability is tricky.

4) Level of Detail (LOD) Requirements

Different stakeholders requires varying levels of detail in the BIM models. Determining the right LOD for the complex projects is often difficult especially when the higher detail can dramatically increase the costs and the turnaround time.

Why it’s a challenge:

- Excessive detail inflates the project budgets.

- Insufficient detail reduces the model’s usability.

- Different disciplines may require conflicting levels of accuracy.

5) Coordination Across Disciplines

Scan to BIM projects for the large structures often involves multiple teams handling architectural, structural and MEP systems. Misaligned workflows or poor coordination can lead to errors, duplication or conflicts in the final model.

Why it’s a challenge:

- Diverse software tools and workflows creates the compatibility issues.

- Inconsistent naming conventions and data structures hampers the collaboration.

- Communication gaps across the teams working remotely can cause delays.

6) Time and Cost Constraints

Scan to BIM is already resource-intensive. When applied to the complex structures, the effort required for scanning, processing and modeling increases exponentially. Clients, however, may not always recognize these challenges and expect rapid, cost-effective outcomes.

Why it’s a challenge:

- Increased manpower and computing resources are required.

- Time-intensive manual modeling drives up the project costs.

- Clients demand quick delivery without compromising on the quality.

7) Managing Legacy Structures and Hidden Elements

Renovations of the older buildings often uncovers undocumented structural changes, hidden utilities or deteriorated elements. These features are not always captured in the scans but are crucial for accurate modeling.

Why it’s a challenge:

- Subsurface and hidden components remains unscanned.

- Discrepancies between the historical drawings and the actual structures arises.

- Restoration projects demands the high precision despite the uncertainties.

Strategies to Overcome Scan to BIM Challenges

While the challenges may seem daunting, several best practices and technological advances are helping the AEC professionals overcome these barriers.

1) Use of High-Performance Scanning Technology

Investing in advanced LiDAR scanners, drones and photogrammetry tools ensures the higher accuracy and coverage. Mobile scanning devices also allows the access to difficult-to-reach areas.

Best practices:

- Combines the terrestrial laser scanning (TLS) with UAV-based scanning for the large-scale projects.

- Perform multiple scans at varying angles to minimize the occlusions.

- Use automated registration software to align the scans quickly.

2) Efficient Point Cloud Management

Massive point cloud files can be optimized by filtering the noise and segmenting the data into the manageable portions. Using cloud-based platforms also enhances accessibility for remote teams.

Best practices:

- Utilize point cloud compression without even losing the accuracy.

- Divide large datasets by floor levels or zones for easier processing.

- Leverage AI-assisted software to detect and classify the elements automatically.

3) Custom Family Creation for Non-standard Elements

For irregular geometries and heritage structures, creating the custom BIM families ensures both accuracy and usability. Specialized software plugins can also streamline this process.

Best practices:

- Create reusable parametric families for recurring irregularities.

- Balance the precision with practicality—capture the essential geometry without overburdening the model.

- Use Mesh-to-BIM workflows for highly complex ornamental features.

4) Defining LOD Early in the Project

Establishing the Level of Detail (LOD) at the project’s outset prevents the unnecessary work and ensures the alignment with the stakeholder expectations.

Best practices:

- Conduct stakeholder workshops to agree on the required LOD.

- Apply varying LODs across different building zones based on the project needs.

- Document the LOD guidelines clearly in the project’s BIM execution plan (BEP).

5) Interdisciplinary Collaboration and Standards

Smooth coordination is critical in complex projects. Standardizing workflows, naming conventions and file formats helps to reduce the conflicts across the disciplines.

Best practices:

- Implement a Common Data Environment (CDE) to centralize the project information.

- Use clash detection tools to resolve the conflicts early.

- Schedule the regular coordination meetings to align the stakeholders.

6) Leveraging Automation and AI in Modeling

Manual modeling is time-consuming but AI and automation tools are transforming the Scan to BIM workflows to a greater extent. These technologies identifies the structural components and generates the BIM-ready elements automatically.

Best practices:

- Use AI-powered recognition tools to classify the walls, beams and pipes.

- Automate recurring tasks like as wall extrusion as well as the alignment.

- Employ the scripting tools like Dynamo or Grasshopper for the custom automation.

7) Integrating Facility Data and Historical Records

For legacy buildings, combining the scan data with the archival drawings, photographs and maintenance records helps to fill the gaps in the hidden or inaccessible areas.

Best practices:

- Cross-check the scanned data against the old documentation.

- Consult the facility managers and engineers for the undocumented changes.

- Use NDT methods to detect the hidden utilities.

8) Training and Skilled Workforce

The effectiveness of Scan to BIM heavily relies on the expertise of the professionals involved. Experienced technicians, modelers and BIM coordinators play a crucial role in ensuring accuracy and efficiency.

Best practices:

- Continuously upskill your team with training on the latest software and hardware advancements.

- Encourage the in Scan to BIM tools and methodologies.

- Build multi-disciplinary teams to ensure the holistic project delivery.

Conclusion

Scan to BIM for complex building structures is both a challenge as well as an opportunity. While large datasets, irregular geometries and coordination issues can complicate the process, the benefits far outweighs the difficulties. With the right combination of advanced technology, efficient workflows and even the skilled professionals, these challenges can be systematically overcomed.

Working with an experienced Scan to BIM Company ensures that the stakeholders can navigate these complexities with the confidence. From data capture to the final deliverables, specialized providers deliver accuracy, speed and efficiency—turning the point cloud data into the actionable insights. For projects that demands higher precision, outsourcing to the experts offering the Point Cloud to Revit Modeling Services can be the most reliable path forward.

As the AEC industry continues to push boundaries in retrofits, heritage preservation and large-scale infrastructural projects, Scan to BIM will remain a vital enabler. BIM Companies that invest in robust processes and expertise today will be better positioned to lead the tomorrow’s construction innovations.

In the end, overcoming these hurdles is not just about creating the accurate models—it’s about building smarter, more resilient and future-ready structures.